Continuous Geoelectrical Monitoring vs Traditional Measurements

Tailings dams, while essential for managing mining waste, pose significant challenges due to their potential for failure and the environmental consequences that follow. According to statistics, between 1915 and 2022, there were 376 tailings dam failures worldwide (Center for science in public participation, 2023), resulting in numerous fatalities, environmental pollution, and significant economic losses. These incidents underscore the critical importance of ensuring the structural integrity of tailings dams to prevent disasters and protect communities and ecosystems. In recent years, continuous geoelectrical monitoring, specifically Electrical Resistivity Tomography (ERT), has emerged as a highly effective method for monitoring the stability and integrity of tailings dams.

Moreover, the absence of a standardized monitoring procedure exacerbates the challenge, highlighting the urgent need for a comprehensive approach to dam monitoring and maintenance. Given that the issue of dam failures remains unresolved, implementing standardized monitoring protocols, such as continuous monitoring with innovative technologies, is crucial for mitigating risks and ensuring the long-term stability of tailings dams.

Traditional methods of monitoring tailings dams often involve manual inspections, periodic sampling, and use of various instrumentation such as piezometers, inclinometers, and surveying equipment. While these methods have been effective to some extent, they come with several limitations compared to autonomous geoelectrical monitoring systems:

- Limited Coverage: Traditional methods typically cover only specific points or areas within the tailings dam, leading to potential blind spots.

- Temporal Resolution: Manual inspections and periodic sampling provide only snapshots of conditions at specific times.

- Subjectivity: Traditional methods may rely on subjective interpretation of visual inspections or sample analysis.

- Limited Accessibility: Tailings dams can be challenging and hazardous environments to access for manual inspections, particularly in adverse weather conditions or remote locations.

- Cost and Resource Intensive: traditional monitoring methods require significant resources in terms of manpower, time, and equipment for regular inspections and data collection.

- Response Time: In the event of an emergency or sudden change in dam conditions, traditional monitoring methods may not provide timely alerts.

- Limited Data Integration: Traditional methods may generate disparate data sets from different instruments or inspection reports, making it challenging to integrate and analyze data comprehensively.

- Risk of Human Error: Manual inspections and data collection are susceptible to human error, inconsistencies, and oversight.

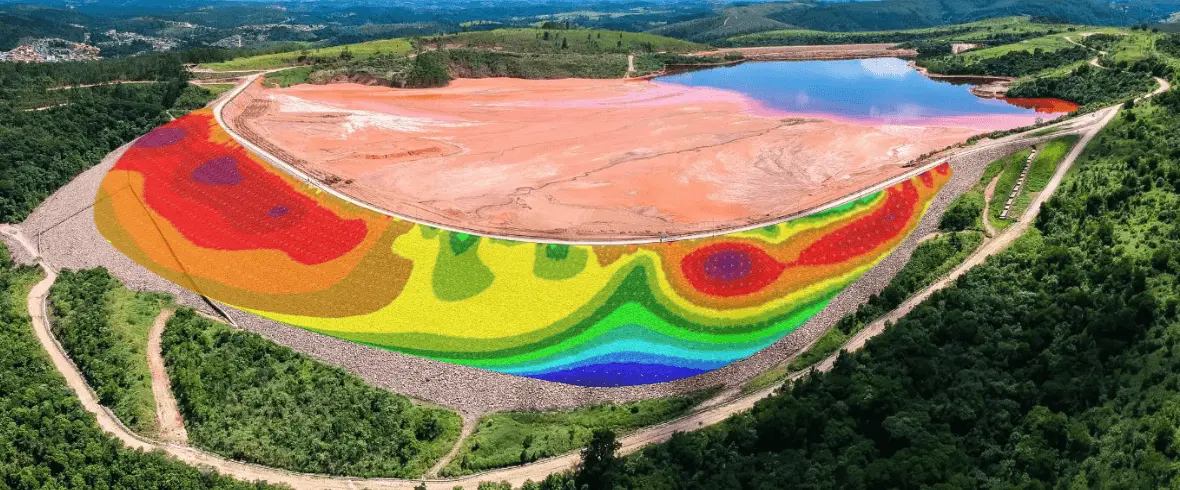

In recent decades, resistivity measurements demonstrate their ability to provide critical insights into the subsurface conditions of tailings dams. By measuring the electrical resistivity of the materials within the dam, moisture content, consolidation, and the presence of potential pathways for seepage or internal erosion can be assessed. This information is invaluable for evaluating the stability and integrity of the dam and guiding decision-making processes related to maintenance, risk management, and disaster prevention.

Real-time and fully autonomous ERT monitoring systems offer unparalleled advantages in terms of effectiveness and reliability. These systems continuously collect data on electrical resistivity variations within the dam structure, providing a comprehensive and up-to-date understanding of its integrity. By offering real-time insights, these systems enable early detection of potential issues, allowing for prompt intervention and risk mitigation measures. Furthermore, their autonomous nature minimizes the need for human intervention, reducing the risk of errors and ensuring uninterrupted monitoring even in remote or hazardous environments.

Here are some key benefits of implementing continuous ERT monitoring:

- Bidimensional Measurements Over a Large Section of Soil: ERT provides a spatially distributed measurements over hundreds of meters, allowing a comprehensive analysis of the dam.

- Time-lapse Analysis of Water Content Changes: The variation of resistivity is mainly related to water content changes in the soil, thanks to processing tools it is possible to analyse the evolution over time, to follow de-watering processing or rainfall infiltration.

- Early Warning of Structural Changes: Continuous ERT monitoring enables the detection of subtle changes in the subsurface structure of tailings dams over time. By continuously monitoring changes in electrical resistivity, potential areas of weakness, structural degradation or seepage can be assessed before they escalate into major problems.

- Improved Safety: Timely detection of changes in dam conditions allows for proactive measures to be taken to mitigate risks and ensure the safety of nearby communities and the environment. By providing early warnings of potential failures, continuous ERT monitoring helps prevent disasters and minimizes the impact of any unforeseen events.

- Cost-Effective Installation and Maintenance: While traditional monitoring methods may require expensive installations, frequent manual measurements and inspections, continuous ERT monitoring offers a cost-effective solution by providing automated, real-time data collection with a low installation cost. This reduces the need for labour-intensive monitoring activities and allows resources to be allocated more efficiently.

- Enhanced Data Analysis: continuous monitoring generates large volumes of data, which can be analysed using advanced algorithms and modelling techniques to gain deeper insights into dam behaviour. This facilitates predictive maintenance strategies and enables engineers to make informed decisions about maintenance and risk management.

- Regulatory Compliance: With increasing regulatory scrutiny on mining operations and tailings management practices, continuous monitoring with ERT helps companies demonstrate compliance with environmental regulations and industry standards. By providing comprehensive and reliable data on dam integrity, mine companies can maintain transparency and build trust with regulatory agencies and stakeholders.

- Long-Term Sustainability: By proactively monitoring and addressing potential issues, continuous ERT monitoring contributes to the long-term sustainability of mining operations. Ensuring the structural integrity of tailings dams minimizes the risk of environmental contamination and helps preserve natural resources for future generations.

In conclusion, continuous geoelectrical monitoring offers significant advantages over traditional monitoring methods for ensuring the structural integrity of tailings dams. By providing real-time data, early warning of potential issues, and cost-effective maintenance solutions, continuous ERT monitoring helps safeguard communities, the environment and the long-term viability of mining operations. Embracing this innovative technology is essential for meeting the evolving challenges of tailings management and advancing sustainable mining practices.